Press Kit | no. 1387-11

NEUF architect(e)s Delivers State-Of-The-Art Jet Manufacturing Facility for Bombardier at Toronto Pearson International Airport

NEUF architect(e)s

New campus replaces the historic Downsview Facility and elevates Bombardier as a global leader in aerospace manufacturing.

Bombardier Inc. (TSX: BBD.B) celebrates the grand opening of its leading-edge Global jet aircraft manufacturing campus at Toronto Pearson International Airport. Designed by NEUF architect(e)s, the 750,000 sq ft facility sets a new standard for enabling precision, efficiency, and sustainability in the aerospace industry, achieving an integrated workplace environment similar in complexity to a healthcare complex.

The new aerospace campus marks a strategic leap forward from Bombardier's decades-old Downsview Airport facility, currently slated for redevelopment. NEUF's purpose-built design incorporates innovative design and modern materials, responding to strict manufacturing processes and regulatory procedures while exceeding international sustainability and safety standards to optimize the assembly and testing of jet aircraft.

"Building an aircraft is an undertaking that rivals the complexity of a major building project," said Graham Kelly, Vice President of Operations for Global Aircraft at Bombardier's Toronto facility. "We needed a space that could not only handle the scale of our manufacturing operations but also reflect our commitment to innovation and exceeding client expectations while ensuring the safety and wellbeing of our employees. " NEUF helped do exactly that.

The new Bombardier facility's production layout enables faster aircraft assembly with complete lines of sight throughout the manufacturing and testing processes. NEUF created an architecture that successfully coordinates specialized teams, automated equipment, robotics, tooling and the mobilization of precision components and instrumentation, resulting in an efficient, accurate and safe production ecosystem where employees work in natural daylight environments with minimal acoustic distractions.

Precise electrical, ventilation, thermal and humidity requirements necessitated a manufacturing strategy that optimizes energy use while reducing waste to align with Bombardier's commitment to environmentally responsible operations. Extensive site engineering was required to incorporate a comprehensive list of fire and life safety requirements within a small, tightly regulated site that minimally impacts neighbouring airport-related services and municipal infrastructure. The NEUF design team led a complex collaboration with the Greater Toronto Airports Authority (GTAA), TÜV SÜD Global Risk Consultants, the City of Mississauga, Transport Canada, and NAV Canada to ensure the facility met the industry's most stringent fire, life safety, and flight operations standards.

As multimillion-dollar jets come to life, NEUF designed all aspects of this 24-hour aerospace manufacturing ecosystem to enhance employee morale and wellbeing, not just their safety. Abundant natural light, dedicated training and collaboration spaces, and visual connections across various functions boost employee motivation and productivity. Minimal travel distances between workstations, offices, and the production floor increase efficiency while contributing to employee interaction and sociability. The interwoven spatial and programmatic complexities within the Bombardier campus are comparable to those of a healthcare facility where safety, clear communication between staff, and precise outcomes depend upon design clarity and rigour.

With a 50-year track record designing industry-specific and complex technology-based projects, NEUF brought their unique expertise and tested design processes to create the latest aerospace manufacturing. They evolved Bombardier's existing manufacturing methodology and identified opportunities for innovation and improvement while working within a tight site, stringent safety protocols, and global aviation standards.

"Designing for aerospace isn't just about the physical structure," said Lilia Koleva, Partner Architect at NEUF. It's about creating a space that perfectly supports Bombardier's workflow, its people, and the meticulous detail that goes into every jet it builds."

Bombardier is one of Canada's most widely recognized businesses and the largest aerospace company in the country. NEUF is proud to have played a role in building the company's next chapter. It shares Bombardier's drive for progress and the continued importance of advanced manufacturing in Canada, which will be studied and admired internationally for its thoughtful design and meaningful advancement of workplace methodology.

Project's Name: Bombardier Aircraft Assembly Centre

Client: Bombardier

Location: Toronto Pearson International Airport, Mississauga (ON)

Surface Area: 750,000 ft² / 69,677 m²

Completed: 2024

Construction Management: Ledcor

Building Engineers: Stantec

Contract Administrator: EXP

About NEUF

Founded in Montreal in 1971, NEUF architect(e)s has grown into one of the largest and most diversified architecture and design firms in Canada. With offices in Montreal, Ottawa and Toronto, the award-winning practice is built around long-lasting client relationships and engaged employees. This collaborative approach has led to the successful completion of over 8,000 projects across the globe. NEUF is well known for delivering exceptional design service in many practice areas, helping build a richly diverse portfolio of work for key Canadian institutions, leading real-estate developers, and cutting-edge manufacturing buildings for international market leaders. Among an extensive list of decades-long client partnerships, Bombardier remains one of NEUF's oldest and most loyal clients.

For more information

Media contact

- NEUF architect(e)s

- Annabelle Beauchamp, Design & Brand Director

- marcom@neuf.ca

- 514 847 1117 #330

Attachments

Terms and conditions

For immediate release

All photos must be published with proper credit. Please reference v2com as the source whenever possible. We always appreciate receiving PDF copies of your articles.

The new Bombardier campus is situated alongside Canada's busiest runway at Toronto Pearson International Airport.

High-resolution image : 13.1 x 14.93 @ 300dpi ~ 7.3 MB

![Press kit | 1387-11 - Press release | NEUF architect(e)s Delivers State-Of-The-Art Jet Manufacturing Facility for Bombardier at Toronto Pearson International Airport - NEUF architect(e)s - Industrial Architecture - <p class="">A specially designed 6-metre-high blast wall [model #G20NB-6] was constructed to protect the airport's operational areas from the powerful jet engine blasts during the testing of the aircraft.</p> - Photo credit: Adrien Williams](https://cloudfront.v2com-newswire.com/data/photo/image/94407/preview_1387-11_94407_sc_v2com.jpg)

A specially designed 6-metre-high blast wall [model #G20NB-6] was constructed to protect the airport's operational areas from the powerful jet engine blasts during the testing of the aircraft.

Very High-resolution image : 22.4 x 14.93 @ 300dpi ~ 13 MB

The new facility features some of the widest aviation doors in the industry, requiring advanced structural engineering and safety protocols.

Very High-resolution image : 22.4 x 14.93 @ 300dpi ~ 14 MB

An exterior view of the Aero-Structural Facility (ASF) and adjacent Flight Test Hangar (FTH).

Very High-resolution image : 22.4 x 14.93 @ 300dpi ~ 16 MB

Very High-resolution image : 22.4 x 14.93 @ 300dpi ~ 15 MB

Very High-resolution image : 22.4 x 14.93 @ 300dpi ~ 17 MB

NEUF produced an architecture that successfully coordinates specialized teams, automated equipment, robotics, tooling, and the mobilization of precision components and instrumentation, resulting in an efficient, accurate, and safe production ecosystem.

High-resolution image : 16.93 x 11.42 @ 300dpi ~ 8.9 MB

From specialized trenches and floor design to ample daylighting, integrating innovative design and materiality optimizes the manufacturing processes of Bombardier's jet aircraft.

Very High-resolution image : 14.93 x 22.4 @ 300dpi ~ 15 MB

The testing and finishing of Bombardier's flagship Global 7500 jet aircraft.

Very High-resolution image : 22.4 x 14.93 @ 300dpi ~ 14 MB

A Global 7500 goes through a testing process, requiring extensive overhead ventilation and fire safety controls, with comprehensive underfloor services.

Very High-resolution image : 22.4 x 14.93 @ 300dpi ~ 13 MB

Careful attention is paid to ensuring that the aircraft's most valuable component—its jet engines—is precisely integrated with the fuselage and wings.

High-resolution image : 11.12 x 14.93 @ 300dpi ~ 6.3 MB

NEUF integrated the largest overhead doors in the industry into the new testing facility, where several planes can safely enter and leave in preparation for interior finishing and painting at Bombardier's Montreal factory before final delivery to the client.

Very High-resolution image : 14.93 x 22.4 @ 300dpi ~ 13 MB

The testing and finishing of Bombardier's flagship Global 7500 jet aircraft.

Very High-resolution image : 14.93 x 22.4 @ 300dpi ~ 14 MB

Very High-resolution image : 22.4 x 14.93 @ 300dpi ~ 13 MB

Controlled entry access for employees features a floating artificially illuminated ceiling and contrasting materials to facilitate movement and orientation.

Very High-resolution image : 14.93 x 22.4 @ 300dpi ~ 7.6 MB

Inspired by flight: the Bombardier office reception area incorporates wing-shaped baffles overhead and a floating desk set within an abstracted cloud.

Very High-resolution image : 22.4 x 14.93 @ 300dpi ~ 12 MB

Dedicated training and collaboration spaces maximize daylight and visual connections to promote employee motivation and productivity.

Very High-resolution image : 22.4 x 14.93 @ 300dpi ~ 12 MB

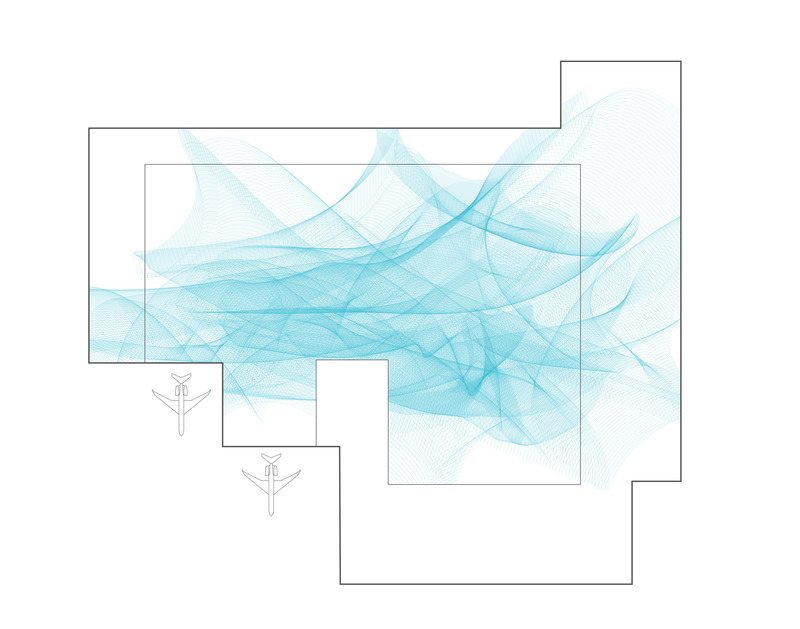

Just as countless lines on a map illustrate the flight paths of aircraft moving around the world at any given moment, this diagram captures the complexity and precision of aircraft assembly. Orchestrating thousands of operations and simultaneous interactions between specialists are required to integrate parts, expertise and safety checks into a finished product—a Bombardier global jet.

High-resolution image : 14.0 x 11.0 @ 300dpi ~ 6.4 MB

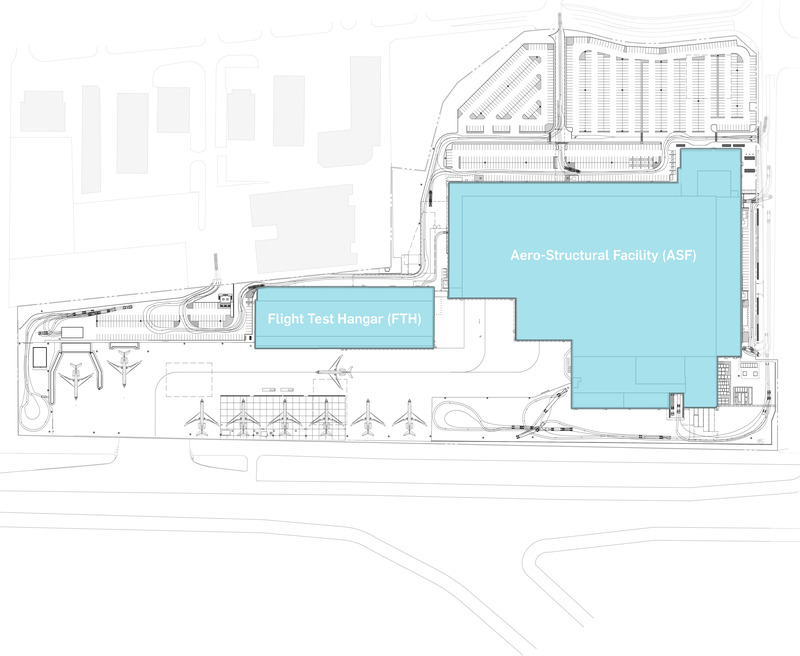

Located alongside Canada's busiest runway, the 750,000-square-foot campus comprises two independent buildings, a blast wall, a material storage area, and clear paths for circulation.

Very High-resolution image : 19.21 x 15.75 @ 300dpi ~ 2.5 MB

High-resolution image : 12.0 x 8.0 @ 300dpi ~ 840 KB